Table of Contents

Introduction

Are you familiar with the term “lead time” but do not have a clear idea about its meaning or relevance to your business?

Lead time is a critical concept that should be well understood by anyone trying to deliver smooth services and products.

It is one of the fundamental concepts in business and has a strong influence on all industries or sectors of an organization, including

- Production

- Inventory management

- Customer service

With the correct knowledge and grasp of lead time, you can increase your productivity and overall profitability.

This blog post will discuss lead time, ways to reduce lead time, lead time optimization tools like Workstatus, and more.

Let’s dive in.

Understanding Lead Time

Lead time is the total time it takes to complete a particular task or process. It starts when you begin working on something and ends when you finish.

Understanding lead time is important because it helps you plan. If you know how long it takes to make a product, you can order materials early enough.

That way, you don’t run out and delay orders. Short lead times mean you can deliver to customers faster. But if lead times are too long, you might disappoint customers.

Managing lead time well helps your business run smoothly. It will help you keep customers happy by avoiding missing deadlines. It enables you to use time, people, and resources more effectively.

Difference Between Lead Time And Cycle Time

Lead time and cycle time are related but different concepts. Lead time is the total time taken from start to finish, while cycle time only looks at the actual work being done.

For example, making a chair takes 5 days of lead time, but the cycle time is just 3 days of active work. The other 2 days are spent waiting for materials or approvals. Understanding cycle time helps optimize the working process.

Reducing idle time can improve efficiency. Lead time considers all delays and waiting periods, too.

Don’t know how to track idle time?

Workstatus can help you view how much idle time happens during the day. That way, you can spot any inefficiencies quickly.

Maybe certain steps get stuck waiting for approvals. Workstatus data shows you where your cycle time is getting delayed. You can then fix those bottlenecks and cut down idle periods.

Less idle time means your team works more productively. Your cycle times get shorter, and lead times improve, too.

Deliver faster to customers by reducing idle time with Workstatus.

Calculating Lead Time

If you’ve been performing certain processes for a while, you likely already have a rough idea of their duration.

You might estimate that it takes a customer six days to place an order and receive it, or you might guess that your team takes 10 days to create and publish a blog post.

But when it comes to lead time, you can’t just operate on a hunch or best guess. It’s important to try to get a solid and realistic understanding of your lead time so that you can:

- Plan projects and tasks more efficiently

- Avoid unexpected bottlenecks and delays

- Effectively allocate labor and other resources

- Set proper expectations with customers or stakeholders

So, how do you calculate lead time?

Since lead time applies to many different scenarios, there isn’t one right way to calculate it — different industries and teams use entirely different approaches.

Let’s look at some of the most common methods for calculating lead time.

How To Use Lead Time Formula?

Here are some simple steps that will help you to calculate lead time:

Step 1: Identify the process you want to measure from start to finish (e.g. product or service).

Step 2: Note down the start and end dates/times of the process. The duration between them is the overall lead time.

Step 3: Break down the lead time into processing times and delay times.

Processing times are periods when actual work happens.

Delay times are periods of inactivity or waiting.

Step 4: Add up all the processing times to calculate the cycle time.

Step 5: Add the cycle time and delay times together using this formula:

Total Lead Time = Cycle Time + Delay Times

Step 6: The result gives you the total lead time for that process.

Using this lead time formula helps predict completion dates accurately when planning and scheduling tasks.

Understanding Lead Time Formula With Example

Suppose your company is releasing a new software product. You need to calculate the lead time from project initiation to final delivery.

First, note the start and end dates. The project starts on June 1st, and the planned launch date is September 30th.

Next, break down the tasks and timelines:

June 1-15: Requirements gathering (2 weeks processing time)

June 16-30: Delay for resource allocation (2 weeks delay)

July 1-31: Design and prototyping (1 month processing)

August 1-15: Testing (2 weeks processing)

August 16-31: Delay for bug fixes (2 weeks delay)

September 1-25: Final development (3 weeks processing)

September 26-30: Preparatory work for launch (1 week processing)

The total cycle time (active work) is: 2 weeks + 1 month + 2 weeks + 3 weeks + 1 week = 12 weeks

The total delay time is: 2 weeks + 2 weeks = 4 weeks

Using the formula:

Lead Time = Cycle Time + Delay Time

Lead Time = 12 weeks + 4 weeks = 16 weeks

So, the lead time from project initiation to software launch is 16 weeks or approximately 4 months.

From Slow To Swift: Optimizing Lead Time With Workstatus

Here’s how Workstatus can help you optimize lead time:

1. Schedule Planner

The Schedule Planner in Workstatus lets companies visually map out projects and allocate team resources effectively.

With an intuitive calendar view, managers can distribute work to team members based on their roles, availability, skill sets, and workloads.

This helps optimize lead times by:

- Ensuring work is appropriately distributed across the team to prevent bottlenecks

- Giving visibility into team bandwidth to take on new projects

- Allowing for a better balance of priorities and deadlines

- Enabling easy rescheduling of tasks if delays occur

Using the Schedule Planner, companies can plan projects more realistically from the start and adapt quickly when changes happen – reducing overall lead times.

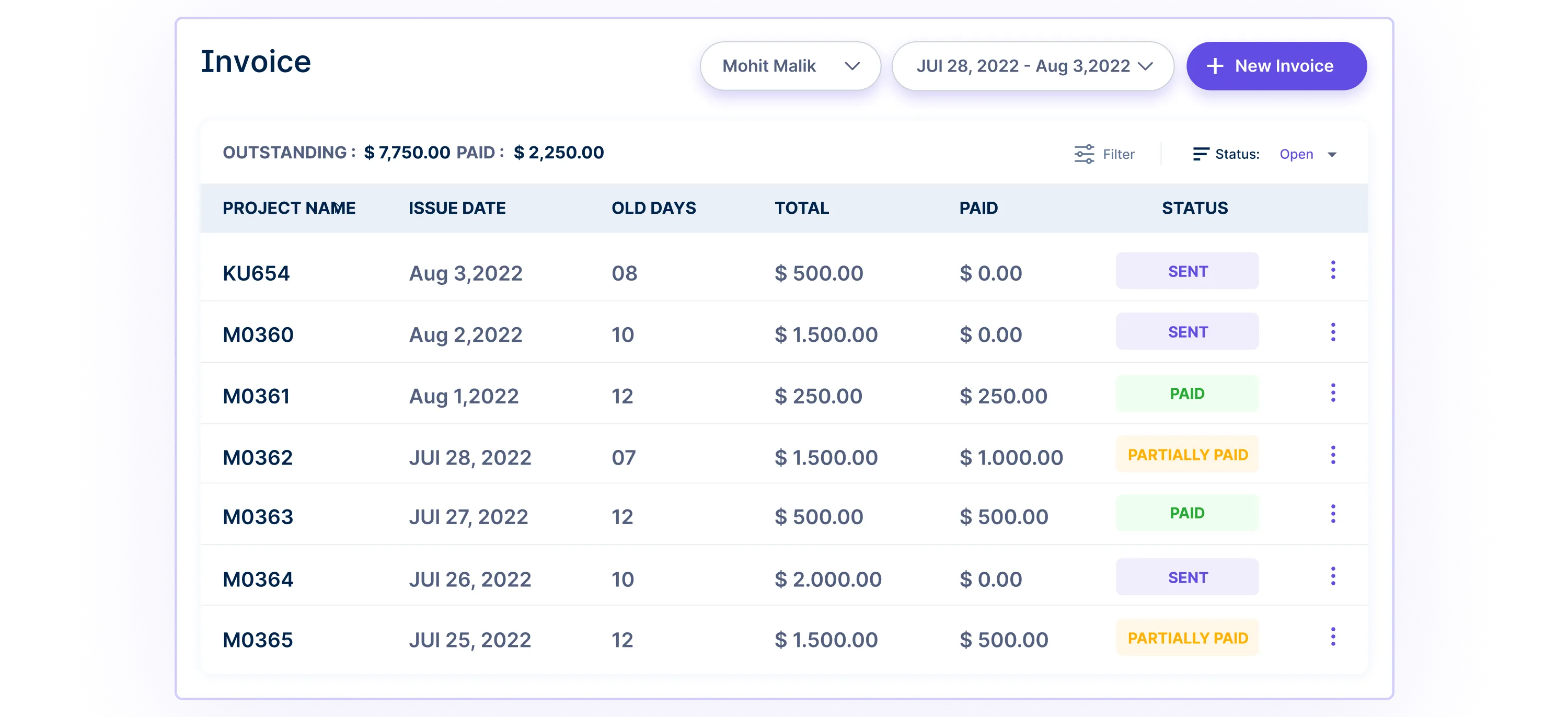

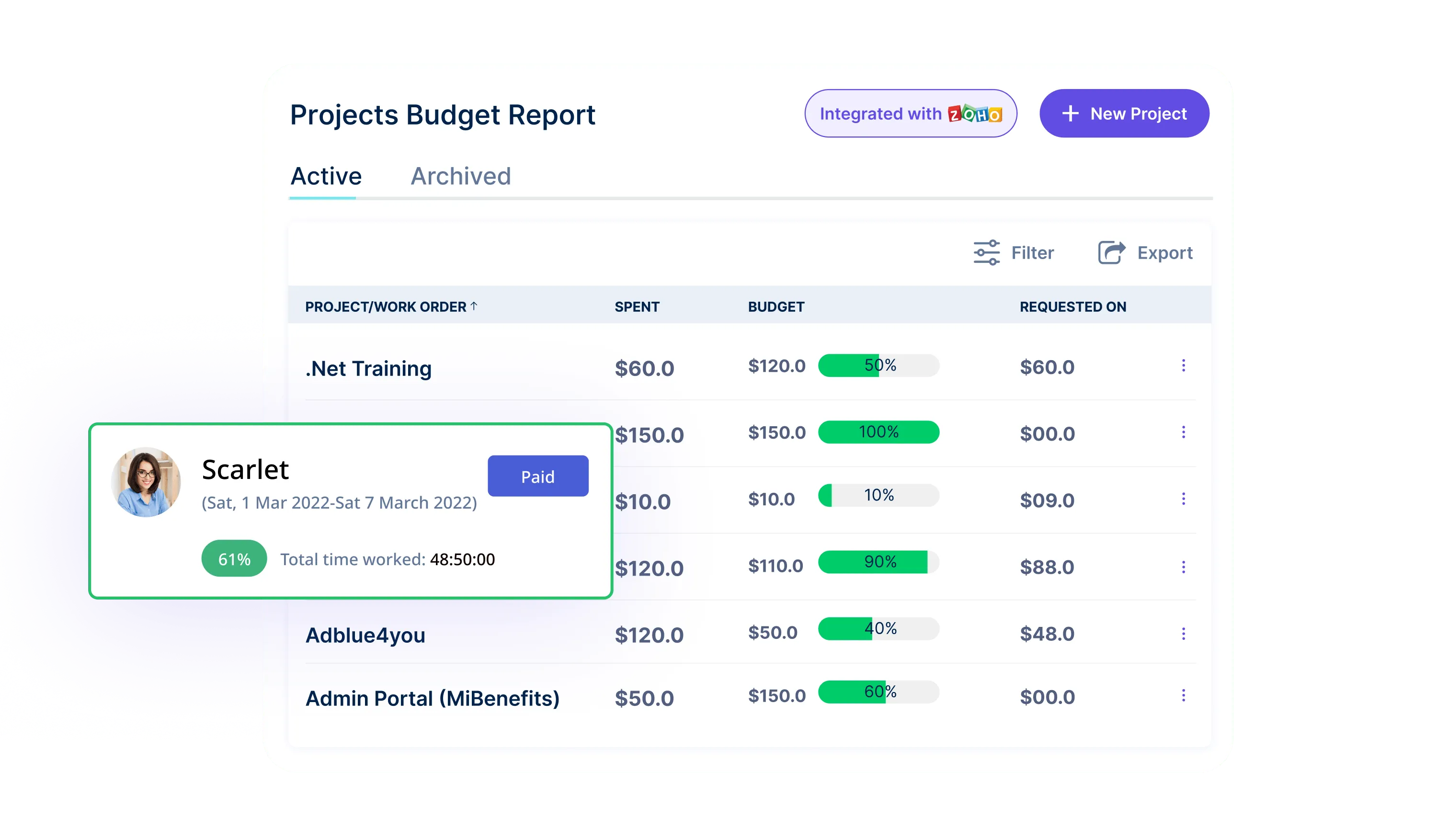

2. Invoice Management

Inefficient invoicing processes can significantly delay payments and cash flow.

Workstatus’s Invoice Management toolkit to streamline this area by allowing companies to:

- Automatically generate invoices based on time-tracked

- Save invoice templates for faster creation

- Accept online payments through integrated gateways

- Send payment reminders and late fees

- View comprehensive reporting on invoicing status

By simplifying and accelerating invoicing, companies can get paid quicker after completing projects.

This improved cash flow allows them to invest in more resources to take on additional work with shorter lead times.

3. Online Timesheets

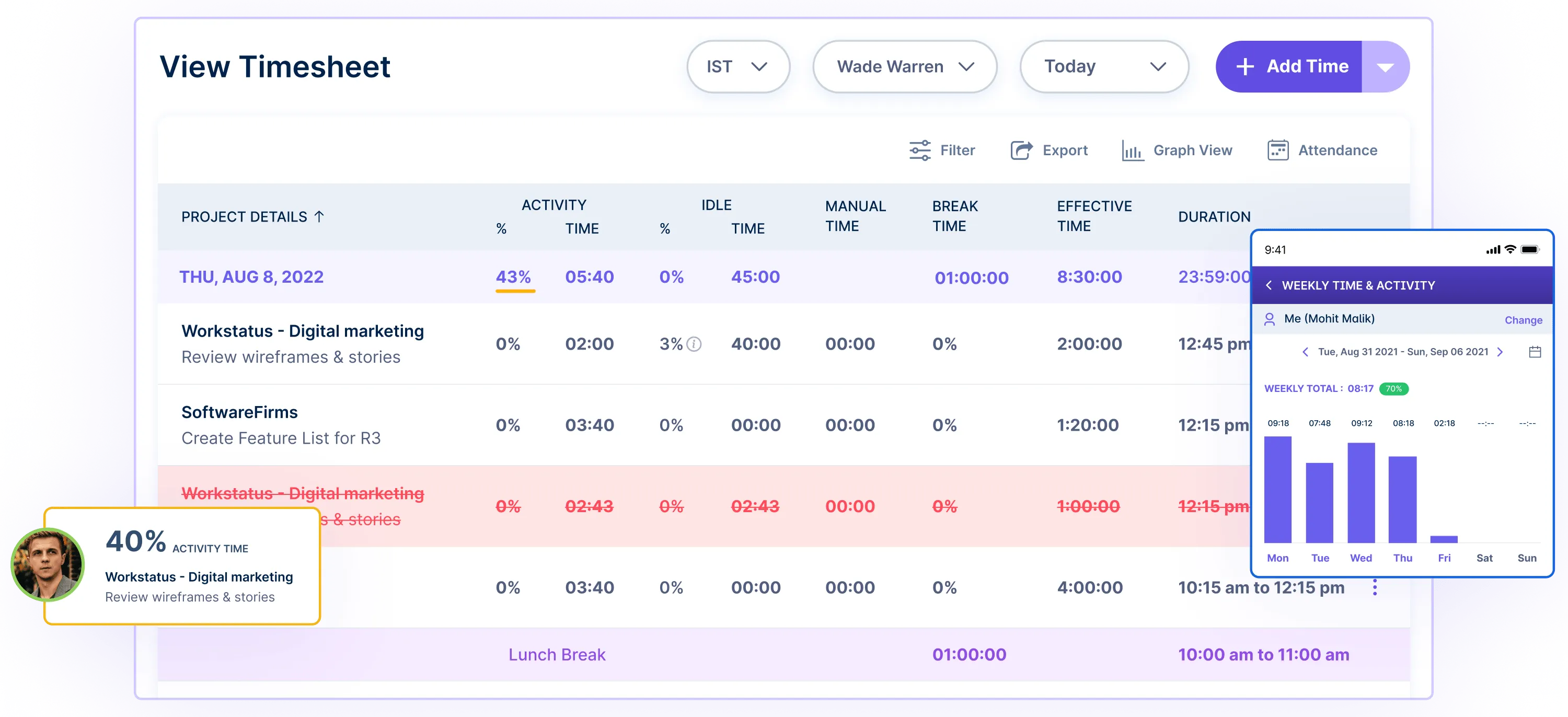

Online timesheets provide a centralized place to view all time logged by employees, contractors, or clients.

Reviewing and approving these sheets helps validate time spent on project phases before billing or closing out.

This reduces payment delays that could impact lead times.

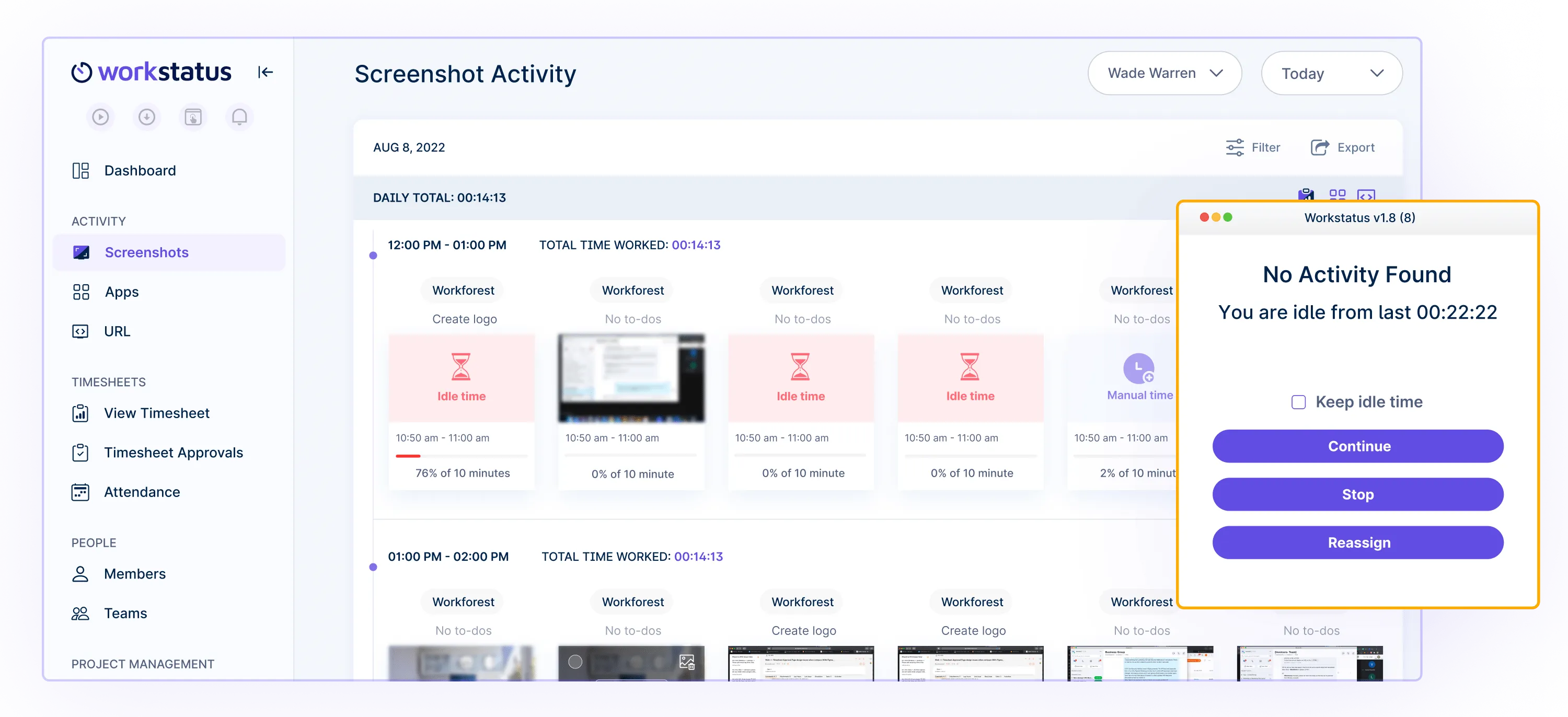

4. Activity Levels

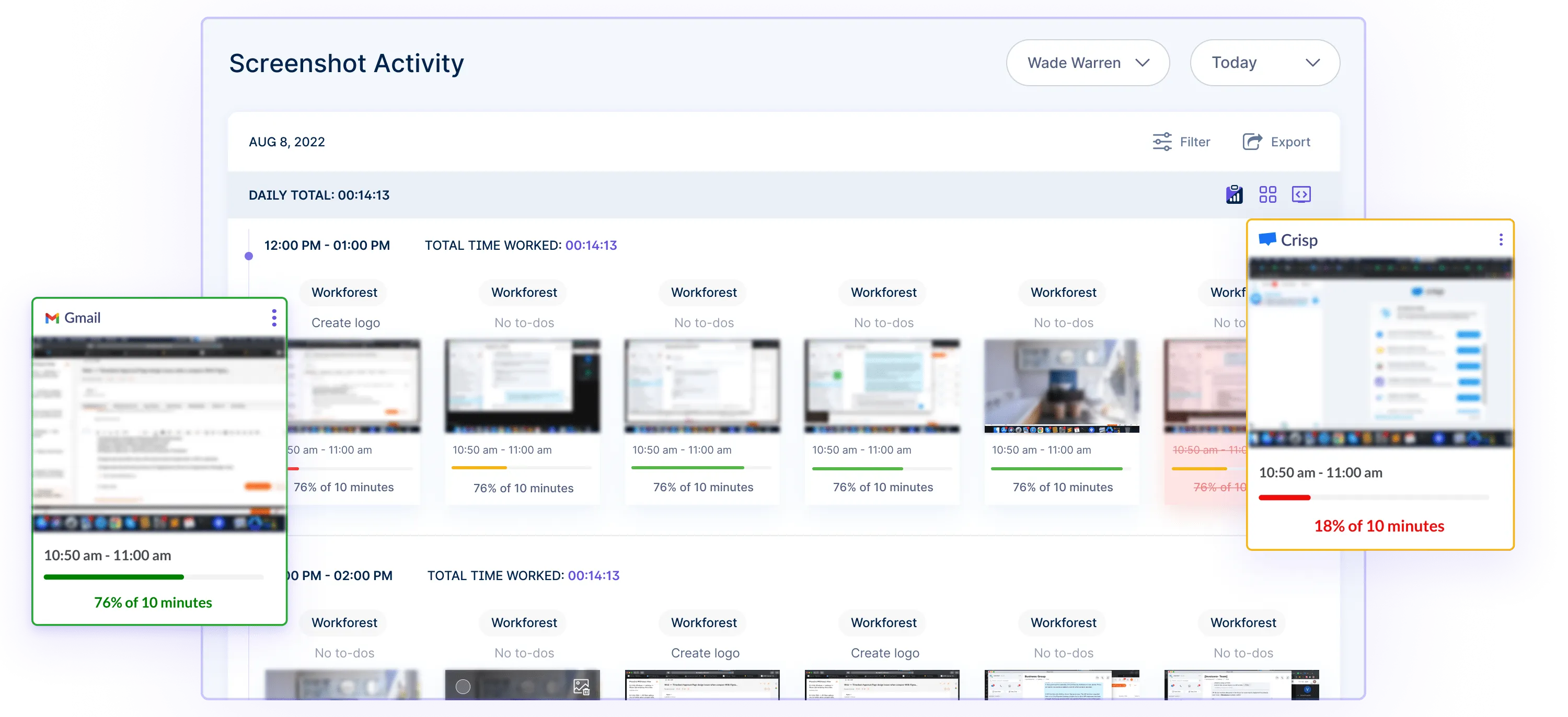

Workstatus tracks team members’ activity level so you can ensure teams stay focused and productive throughout the project timeline.

![]()

You can keep a track of apps & URLs visited by your team members and access real-time screen captures as a proof of work for employees.

It helps reduce delays caused by distractions or low productivity.

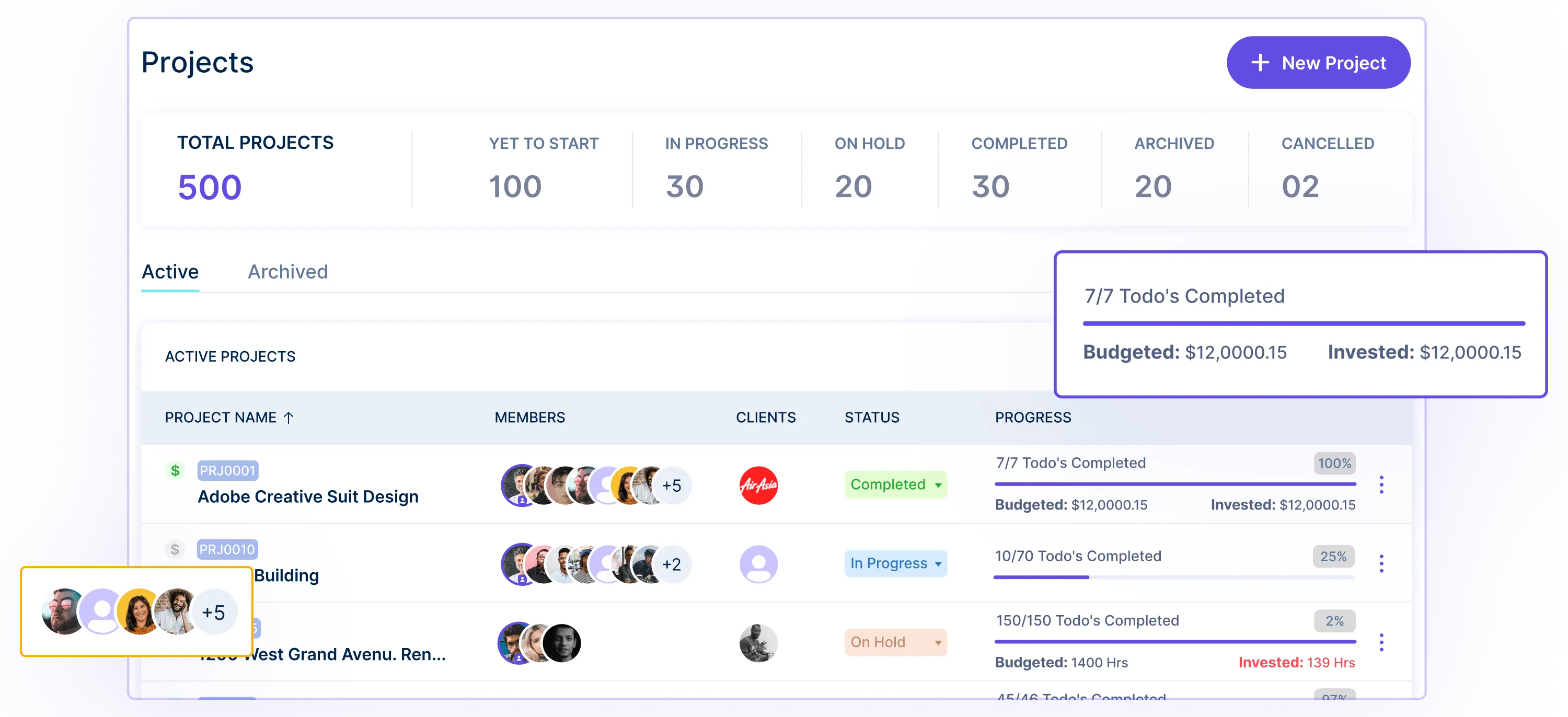

5. Project Management Tools

The project management tools in Workstatus allow tasks to be assigned, tracked, and prioritized effectively.

It streamlines workflows and communication to keep projects moving forward efficiently. For enhanced project visuals, teams can even use an AI image generator to create quick, professional assets, streamlining workflows and communication.

6. Project Budgeting

Companies can set project budgets based on payment amounts or estimated time requirements.

As time gets logged, the budget updates in real-time.

This visibility helps keep projects from going over budget and allows adjusting scopes or bringing in more help if needed to maintain lead times.

Key Benefits:

- Increased Visibility: Get insights into time spent and productivity levels to identify improvement areas.

- Faster Turnaround: Streamlined processes and efficient team management help reduce delays and complete projects sooner.

- Cost Savings: By increasing productivity and reducing administrative overhead, companies can deliver more projects for less cost.

- Better Planning: Historical data on past lead times enables more accurate planning and resource allocation for future projects.

- Improved Profits: Shorter lead times mean getting paid faster and increasing profitability.

Overall, Workstatus’s powerful yet easy-to-use toolkit provides companies with the data, tools, and capabilities they need to complete projects quickly and efficiently.

Things To Consider While Calculating Lead Time

Here are some major things to consider while calculating lead time:

1. Don’t skip the details

If you’re in manufacturing, there are a couple more terms you’ll need to know:

After Receipt of Order (ARO): This indicates that the timeline or countdown for payment, delivery, or something else officially begins when the order is received.

Manufacturing lead time means the amount of time it takes for a manufacturer to produce and ship the goods.

It’s especially relevant for retailers who don’t make their own products and rely on third-party manufacturers to send products to them before sending them to customers.

Retailers must keep track of this time when calculating their total lead time.

2. Review actual data

Your lead time calculations need to be as accurate as possible to be as helpful as possible.

Look through reports to get a more realistic understanding of how long things actually take.

You might realize that a typical blog post draft takes three days—not one day like you originally estimated.

3. Build in some extra time

You know the saying about even the best plans not working out perfectly? That’s why it never hurts to add a little extra time to your lead time calculations.

Don’t overdo it, as accuracy still matters. But it’s better to estimate a higher lead time and deliver early than to estimate too low and deal with missed deadlines and disappointed customers.

It’s always better to underpromise and overdeliver, rather than the other way around.

Strategies To Minimize Lead Time

Here are some strategies that you can use to minimize your lead time:

1. Streamline Your Supply Chain

For manufacturers, there may be opportunities to streamline the supply chain and reduce lead times. Some ideas:

- Place smaller but more frequent orders with suppliers instead of large infrequent orders

- Source suppliers located closer to your facilities to minimize shipping distances

If you’re not in manufacturing, apply similar thinking to any process.

For example, engage freelancers for specific skills rather than waiting on in-house staff availability.

2. Nurture Supplier Relationships

Strong business relationships are key to keeping lead times under control.

Manufacturers could incentivize priority fulfillment for their orders with vendors. For project work, you could retain freelancers to get preferential scheduling.

The goal is to foster good working relationships so suppliers prioritize your needs when you need them, reducing lead times.

3. Identify Dependencies and Parallelization

Dependencies between tasks can significantly impact lead time calculations that sum process steps.

For example, editing a blog post depends on the draft being done first. A delay in drafting directly adds to the total lead time.

Conversely, look for tasks that can run concurrently. Graphics could potentially be designed in parallel with drafting to shave time off the end-to-end process.

4. Use Automation

Automating repetitive tasks eliminates inefficient manual efforts and reduces lead times. Simple automations can include:

- Online forms capturing all project requirements up front

- Automated task creation in project tools based on templates

- Alerts for reordering inventory based on stock levels

Automating the above steps lets you maintain reasonable lead times.

Closing Thoughts

In the end, understanding and calculating lead time is all about setting proper expectations and planning effectively.

By taking the time to accurately measure how long processes really take, you can schedule projects realistically.

This helps avoid missed deadlines, wasted efforts, and disappointed customers.

Though there are many nuances, the core idea is simple – determine each step’s duration, account for dependencies, and build in a safety buffer.

With clear lead time data driving your plans, you’ll be able to optimize workflows and drive your business forward smoothly.